Get to know your oil tank

Know what tank you have

It’s important you know what type of tank and pipework arrangement you have and how to use it. Your tank manufacturer, installer, maintenance engineer or oil delivery company should be able to help you.

What’s your tank made from?

Oil tanks come in many shapes and sizes, usually they’re manufactured from steel or plastic and have other equipment and pipes attached.

Plastic tanks are made of moulded polyethylene, come in different shapes and are normally green. Steel tanks are usually rectangular and are protected with an oil resistant coating. You’ll need to maintain the coating to prolong the life of a steel tank.

For all tanks it’s important to follow your tank manufacturers’ maintenance instructions or ask your inspection engineer for advice.

What type of tank do you have?

Different types and styles of tanks exist depending on the manufacturer, what the tank’s used for and where it’s installed. It’s important to understand the level of spill protection your tank system provides.

Single skinned

An oil storage tank with only one layer of steel or plastic to contain the fuel is called a single skinned tank. This type of tank gives the lowest level of protection as oil will escape if the single layer of plastic or steel is damaged. To increase the level of oil spill protection we recommend a single skinned tank is put into a constructed masonry or concrete bund, this second protective layer is called a secondary containment system. It’s important to note that basic masonry or concrete is not impervious to oil; your secondary containment will need to be sealed to create an effective bund. Legislation requires some single skinned tanks to be located within a bund or secondary containment system.

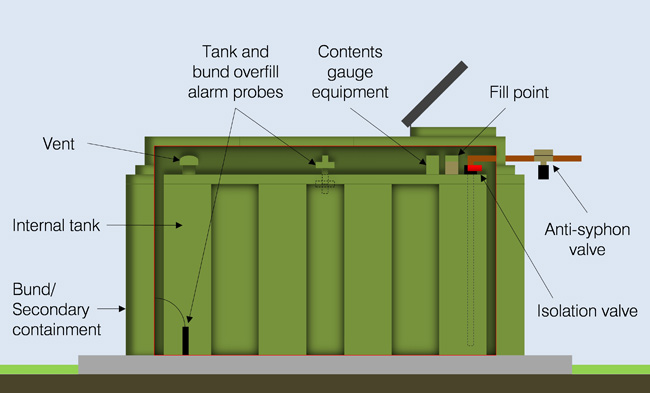

Integrally bunded

An oil storage tank which comes within an attached larger bund is called an integrally bunded tank. The integral bund is designed to hold 110% of the inner tank’s contents and all of the oil tank fittings, including any vents or pipes. Integrally bunded tanks are supplied as a package unit and provide an improved level of oil spill protection.

Refuelling station

An integrally bunded plastic or steel tank system for dispensing fuel for vehicles or plant machinery is called a refuelling station. These units are specially designed to capture any fuel that is spilt as you refuel vehicles or equipment, protect against theft and allow measurement of any fuel dispensed.

Double skinned

Otherwise known as a twin walled tank. They have an inner tank surrounded by an outer larger tank for extra strength. The outer tank or skin isn’t large enough to contain 110% of the inner tank oil volume so they won’t give you the level of spill protection which is provided by an integrally bunded tank. As they aren’t located in a bund they don’t give the same protection against oil loss from overfilling the tank or damage to the tank or any pipe work.

As with single skinned tanks we recommend that above ground double-skinned tanks are installed in a bund or secondary containment system, in some cases this may be a legal requirement.

Underground tanks

Sometimes the only visible part of an underground tank you can see is the hatch providing access to the fill point, vent and contents gauge.

Underground tanks are harder to look after because you can’t see them to check for damage, leaks or spills. It’s very important to monitor how fast you use oil from an underground tank. If your oil suddenly starts going down you should ask a qualified competent person who is registered to perform oil service work to check your tank and pipework isn’t leaking.

The fittings on your tank

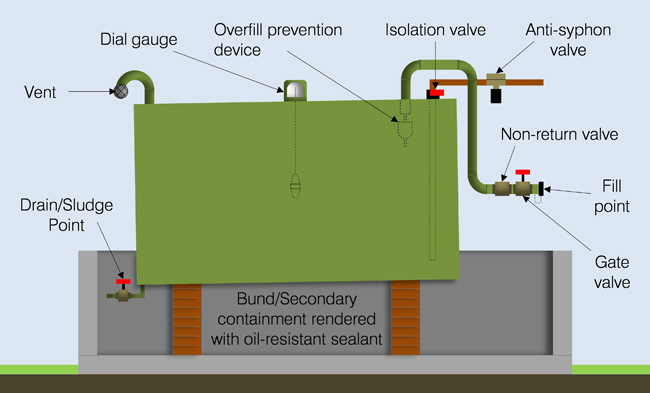

Fill point

A threaded pipe coupling that the oil delivery driver connects onto to fill the tank, usually 2 inches or 50mm in diameter. The fill point may be on the tank or a pipe may be extended to a remote fill location. You should have a drip tray for all remote fill pipes to catch any drips that can’t drain to your tank. Check the drip tray at the same time as you make regular checks of your tank.

Vent

A means of releasing vapour and air from the tank into the atmosphere when the tank is being filled and air into the tank when fuel is drawn off. It’s important to keep vent outlets clear to allow a free passage of air in and out of the tank. The vent pipe diameter should be at least as big as the fill pipe (usually 2 inches or 50mm in diameter).

Contents gauge

A device that indicates the quantity of oil in the tank. Gauges can be manual, visual or wireless. The reading may be seen at the tank, next to the tank or even at a remote location (for example in the kitchen). All contents gauges must be correctly selected for the tank being monitored so they give accurate readings.

You should take special care with traditional ‘sight tubes’, these are attached vertically on the outside of the tank. They show the oil level in the tank when a valve is opened, don’t leave the valve open, if the sight tube has a problem this can drain your whole tank of oil. The sight tubes need to be securely fixed to prevent sagging and oil leaks.

Isolation valve

Otherwise known as a service valve which shuts off the oil supply from the tank. Normally found at the tank outlet.

Overfill alarm/prevention device

A device to avoid oil spills from overfilling; it can sound an alarm and/or give a visual warning, or automatically stop the oil delivery into the tank.

Bund (also called secondary containment)

An area around the tank designed to contain any loss of fuel and to prevent pollution that will hold a minimum of 110% of the tanks contents. It can be manufactured as part of an integrally-bunded tank or built separately to the tank. A separate bund can be constructed of concrete or masonry then rendered to make it impermeable to oil. If access and health and safety requirements allow; you could put a roof over a separate bund to stop rain water accumulating. There should be no gaps or spaces in the bund walls that allow oil or water to escape to the environment.

Your tank may need to have secondary containment by law depending on where it is and what it’s used for. But, to prevent damage to your property and to protect the environment, you should consider secondary containment, even if it isn’t a legal requirement.

Supply pipework

Oil supply pipes can be: plastic coated copper, steel protected from corrosion or approved plastic pipe (for underground use). Pipes installed above ground should be supported by purpose made clips and attached to permanent structures. Underground pipework should be protected from physical or accidental damage and its route marked with a warning tape which is buried 150mm below the ground surface.

If the pipework serves a non-domestic application, it should incorporate a leak detecting facility. Any underground mechanical joints should be accessible for inspection.